With the focus on the real vehicle test of intelligent vehicles, we provide a full set of real vehicle test solutions with customer demand as the orientation, independent research and development as the driving force, and cooperative integration as the method. With the products covering real vehicle road test, real vehicle field test and real vehicle scene database data collection, we provide a complete set of equipment products from vehicle end to site end. The products include data acquisition and analysis system, driving robot system, target and drive system, etc. We have provided high-quality and satisfactory services for dozens of main unit plants, universities and other customers.

Driving robot, target and driving system, GNSS integrated inertial navigation and other international leading field test equipment

Trajectory control: ± 2cm

Speed control: ± 0.1km/h

Distance control: ± 2cm

Angle control: ± 0.1°

1: 1 copy shape characteristics

Bear the impact without damage

Satisfying sensor perception

Suitable for rain, snow and other environments

Positioning accuracy: 0.01M

Speed accuracy: 0.01m/s

Acceleration accuracy: 1mg

Angle accuracy: 0.01 ° Test assistant system

Vehicle communication equipment

Audio and video monitoring equipment

Alarm signal acquisition equipment

Bus signal acquisition and recording equipment

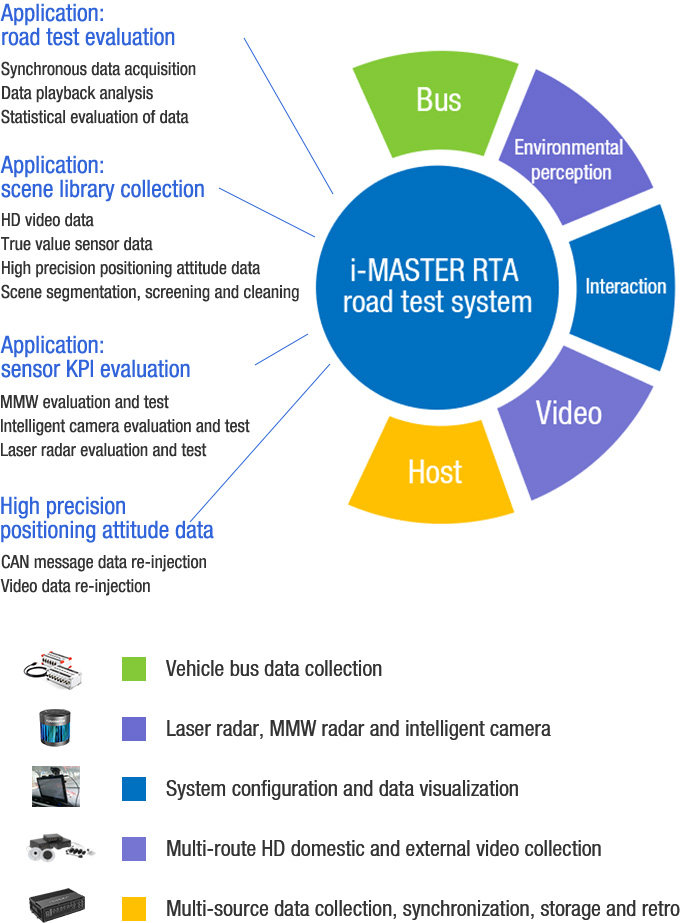

Open road data collection and evaluation equipment for road test, scene database collection and sensor KPI evaluation

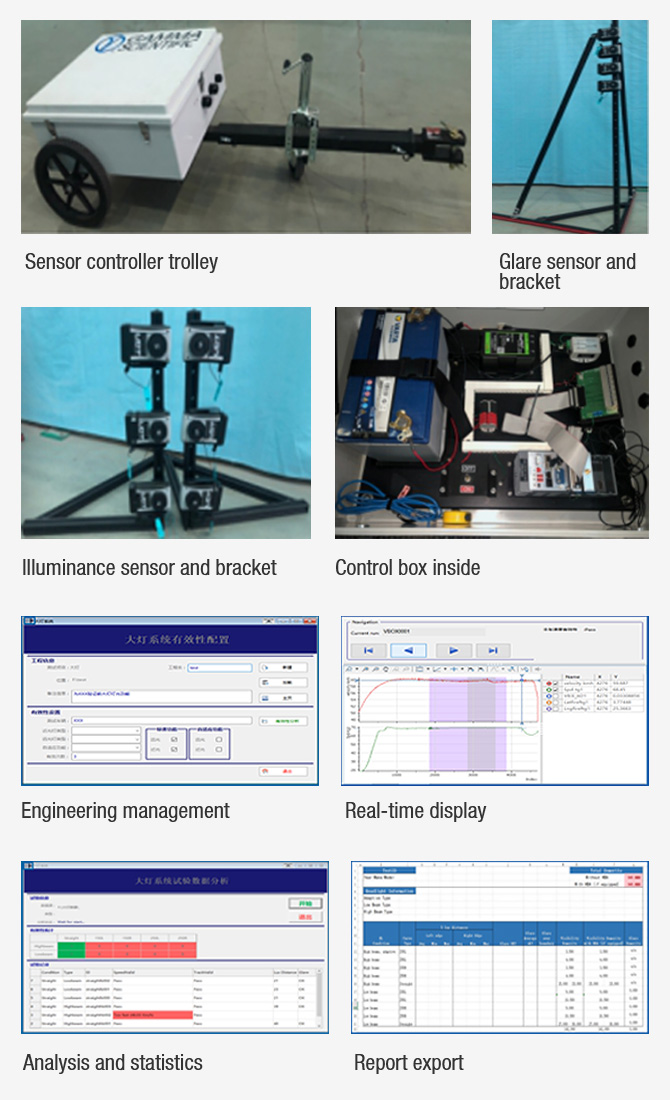

C-IASI2020 vehicle front lamp evaluation special test equipment

Provide intelligent cockpit function, performance, compatibility, stability and other bench or real vehicle test equipment solutions

Non-intrusive test, mechanical arm simulation manual operation, consistent with the users’ actual operation;

Support touch, key operation, including click, double-click, long press, slide and other actions;

Built in coordinate and image recognition operation mode, integrated industrial camera, real-time capture of screen changes;

Integrate all kinds of peripheral access, bus access and sensor to realize the automatic test of the system;

7x24 hours test, no manual intervention, save time and effort.

By simulating manual operation with robot, touch screen automatic test is realized by mechatronics;

Industrial cameras achieve accurate positioning and integrate intelligent image analysis technology to ensure high reliability of test accuracy;

High-precision temperature and humidity environment simulation equipment, restore the user's real use scene;

Stable operation, 7×24 hours uninterrupted and unattended test;

Integrated report function, automatically exports test results.

The artificial mouth and sound pickup are integrated to realize the closed-loop test of speaking, listening, recognition and judgment;

Integrate industrial cameras, touch sensors and other devices to accurately quantify the response time of the equipment;

Compatible with a variety of interactive signal acquisition, IO/bus/audio/touch and other signals;

Support the customization of different test sequences;

Integrate test management functions to effectively manage test cases and tasks and export test reports.

Support automation cases, Python scripts, APK and other automation forms, support the original automation scripts of manufacturers;

Built-in automated test framework, and edit automated test cases through graphical interface;

It has the function of state monitoring to effectively manage the working state of each vehicle;

By integrating task distribution test function, the vehicle can be divided into multiple tasks to perform reliability test simultaneously.